China’s Deep Space Exploration Laboratory (DSEL) in Hefei, Anhui Province, has taken a significant step toward practical lunar construction with the development of a solar-powered system capable of turning Moon dust into building bricks. Published in Acta Astronautica, the work demonstrates how concentrated sunlight can fuse lunar regolith into durable shapes without transporting heavy supplies from Earth—a solution aimed squarely at one of the most expensive bottlenecks in space colonization.

How the System Works — and Why It Matters

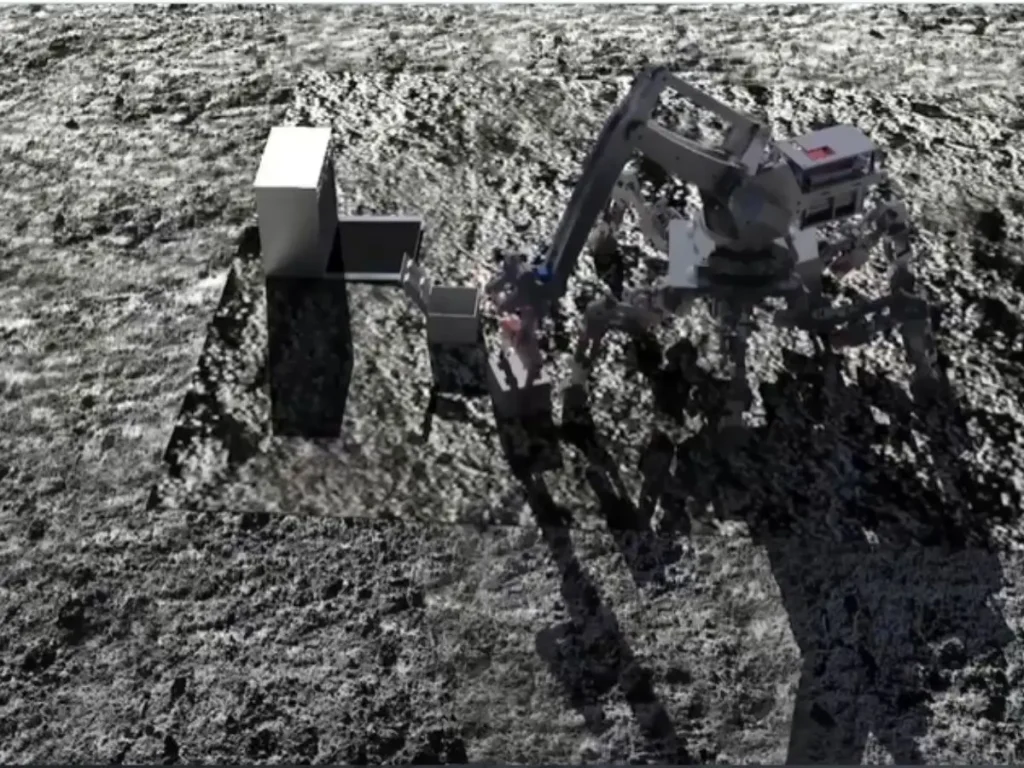

The technology operates like a 3D printer, but replaces electrical or fuel-based heat sources with intense, focused sunlight. A parabolic reflector collects solar energy, which is funneled through bundles of optical fibers to create a beam over 3,000 times stronger than natural sunlight on Earth. At its focal point, the heat soars beyond 1,300°C—enough to melt regolith into dense, load-bearing forms.

Early tests, using basalt-based Moon soil simulants, produced a variety of geometries: flat plates, curved segments, and more complex structural components. These shapes could be used in building habitat shells, roads, and machinery platforms—critical elements for sustaining human presence on the Moon.

If deployed successfully, this method could fundamentally reshape mission planning. Eliminating the need to ship tonnes of construction material from Earth could reduce costs by orders of magnitude, free up launch capacity for other essentials, and allow for larger, more ambitious lunar bases.

Engineering Challenges and Adaptation to the Moon’s Reality

The project’s two-year development cycle was spent wrestling with major technical hurdles. Lunar regolith is not uniform—its composition varies by location, mineral content, and particle size. DSEL engineers simulated several regolith types to ensure the process could adapt to these variations. Energy transmission was another hurdle: focusing and maintaining heat intensity through fiber optics without significant loss required precision design.

Notably, the process uses no additives or binders, meaning it is entirely dependent on in-situ resources. This strengthens its appeal for long-term sustainability but also raises questions about the resulting material’s mechanical performance over decades of thermal cycling and micrometeorite exposure.

Space Station Trials and the Path to Validation

In November 2024, simulated lunar bricks were sent to the Tiangong space station aboard the Tianzhou-8 cargo craft for a three-year durability test. Astronauts will monitor their structural strength, resistance to extreme temperatures, and radiation-shielding performance. The data will determine whether the technology is ready for lunar deployment or if further refinement is needed.

While the testing is rigorous, the space station is not a perfect analog for the Moon’s surface—microgravity and exposure conditions differ. True validation will likely require on-site trials during future lunar missions, something that will test both the technology and China’s robotic construction capabilities.

Strategic Implications in the Lunar Race

Senior engineer Yang Honglun points out a key limitation: these bricks cannot contain pressurised air in the Moon’s vacuum. Instead, they are best suited as protective shells for pressure-sealed habitats, providing shielding against cosmic radiation, micrometeorite strikes, and severe temperature swings. This means they will be part of a layered construction strategy, not a standalone solution.

Still, the implications are significant. A fully automated system for producing and assembling these bricks could allow China to build large-scale lunar infrastructure without constant resupply missions—an operational advantage in the emerging competition for lunar presence.

NASA’s Artemis program is pursuing its own approach to in-situ resource utilization (ISRU), as are ESA and private companies. But China’s focus on a purely solar-powered, binder-free method offers a potentially lighter, simpler, and more scalable path—provided the material properties hold up.

The Critical Questions Ahead

The breakthrough is promising, but several uncertainties remain:

- Material Longevity — Will the bricks maintain structural integrity over decades under the Moon’s day-night thermal extremes?

- Energy Reliability — How will the system perform during the two-week lunar night when sunlight is unavailable?

- Automation Readiness — Can robotic systems reliably produce and assemble bricks in the Moon’s abrasive, dust-laden environment?

- Scalability — Will the technology scale to structures large enough to meet the demands of sustained human activity?

Until these questions are answered, the technology is best seen as a high-potential, yet unproven, enabler of lunar settlement—not a ready-made construction solution. Still, if DSEL can close the gaps, China could secure a pivotal advantage in the race to establish the first permanent base on the Moon—a milestone that would reshape both space exploration and geopolitical influence.